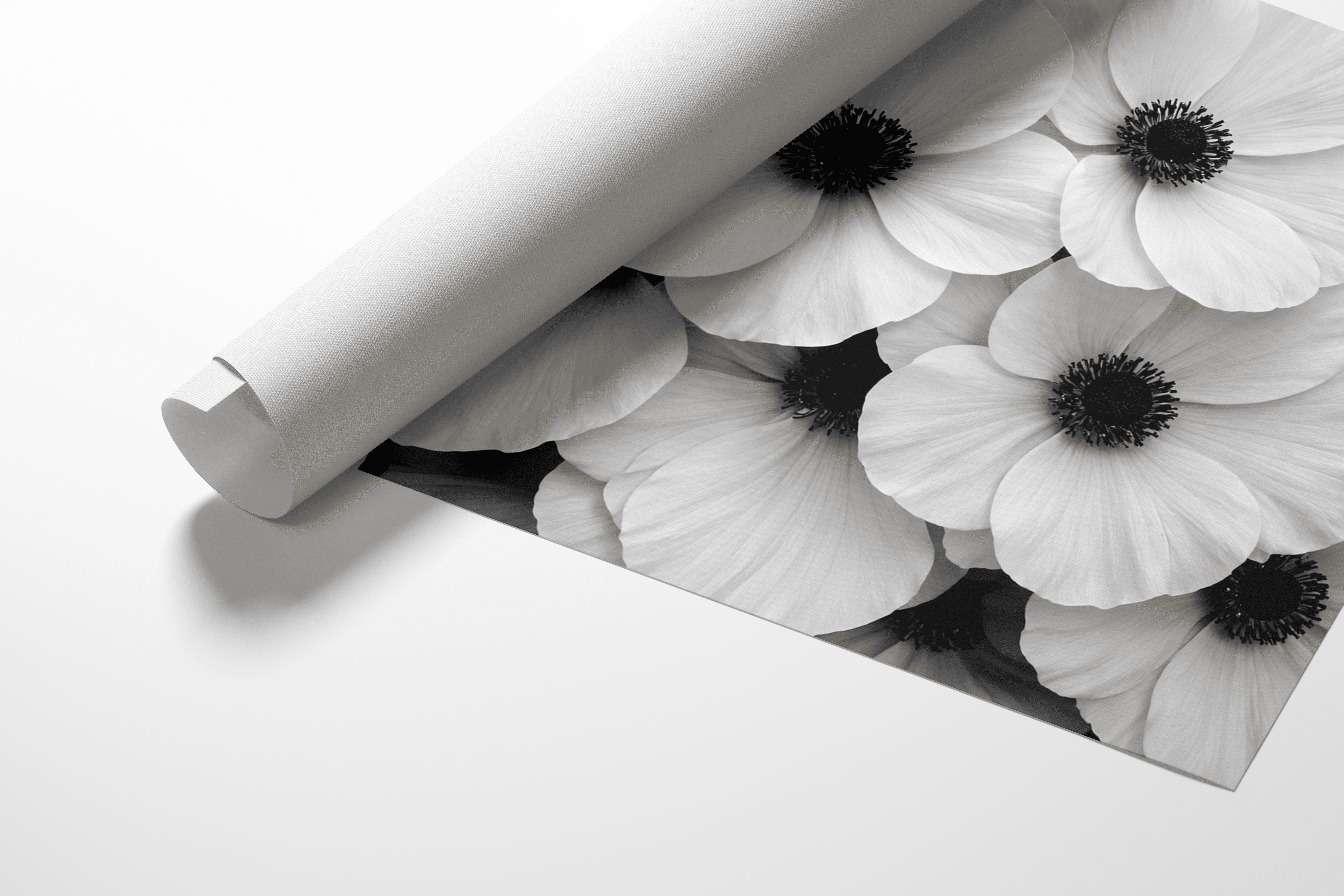

Material innovation without compromise.

Material innovation without compromise.

Material innovation without compromise.

Marine-safe PHA for creative standards.

Marine-safe PHA for creative standards.

Design that

inspires today.

PHA that shapes

tomorrow.

Design that

inspires today.

PHA that shapes

tomorrow.

Design that

inspires today.

PHA that shapes

tomorrow.

NATURE-MADE

Backed by science.

Exclusive marine-safe PHA engineered to return safely to nature.

NATURE-MADE

Backed by science.

Exclusive marine-safe PHA engineered to return safely to nature.

NATURE-MADE

Backed by science.

Exclusive marine-safe PHA engineered to return safely to nature.

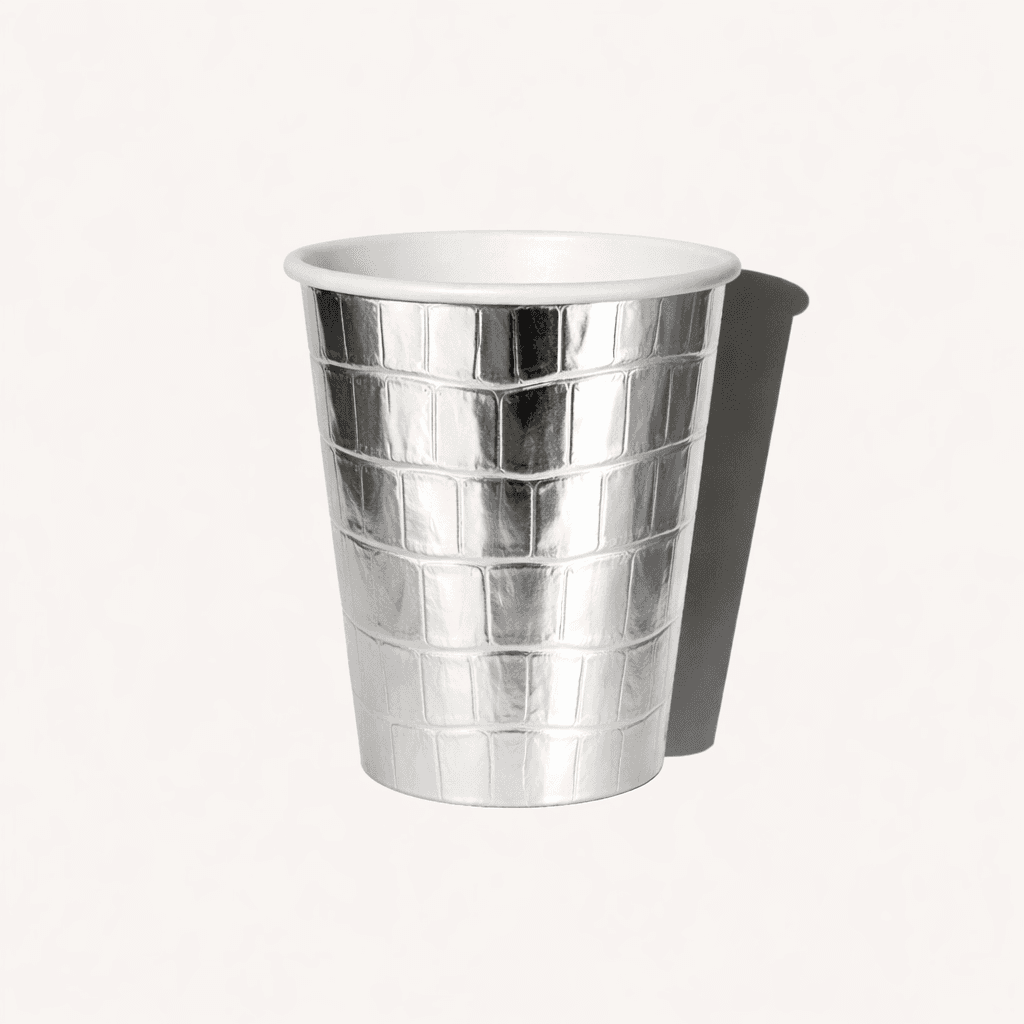

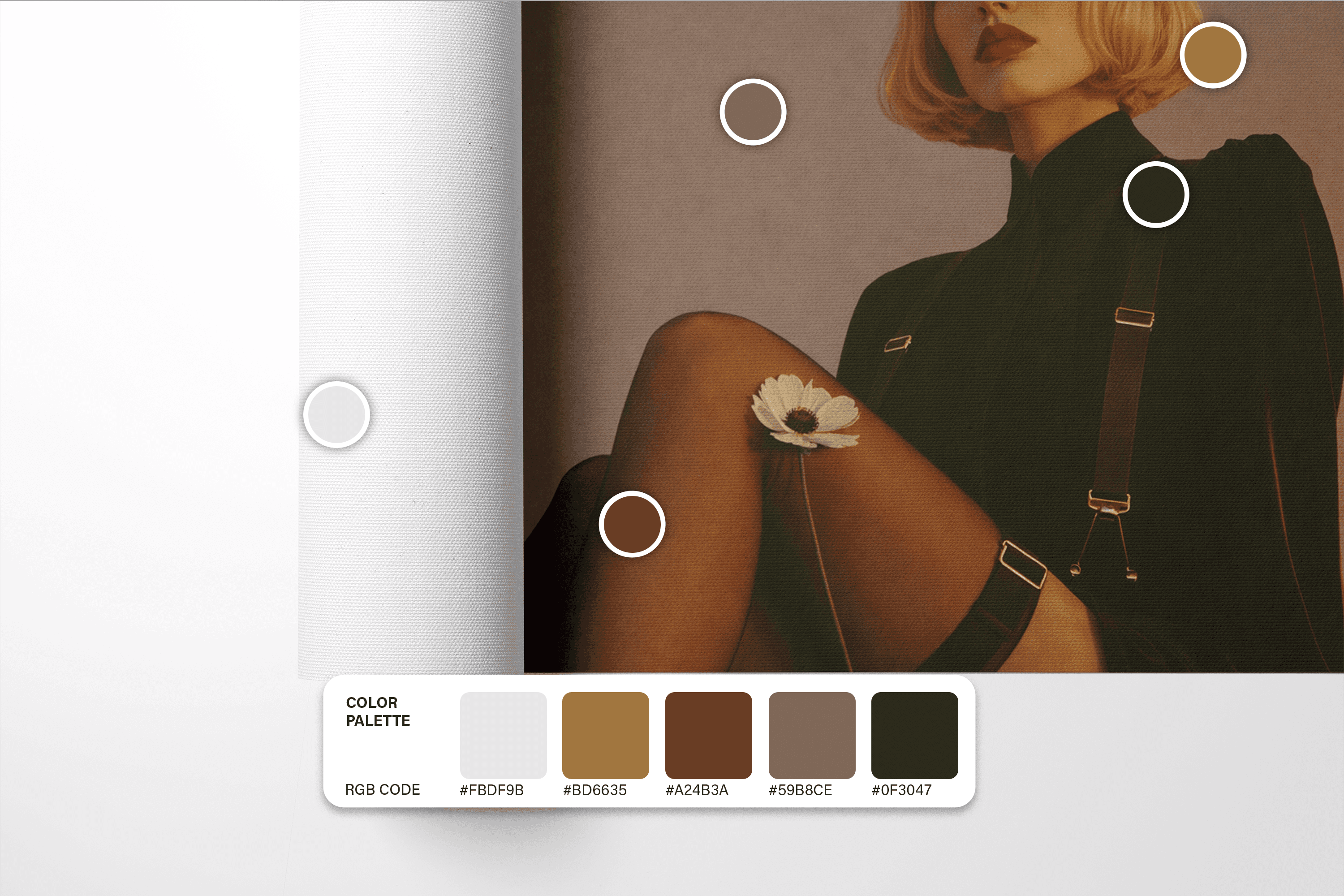

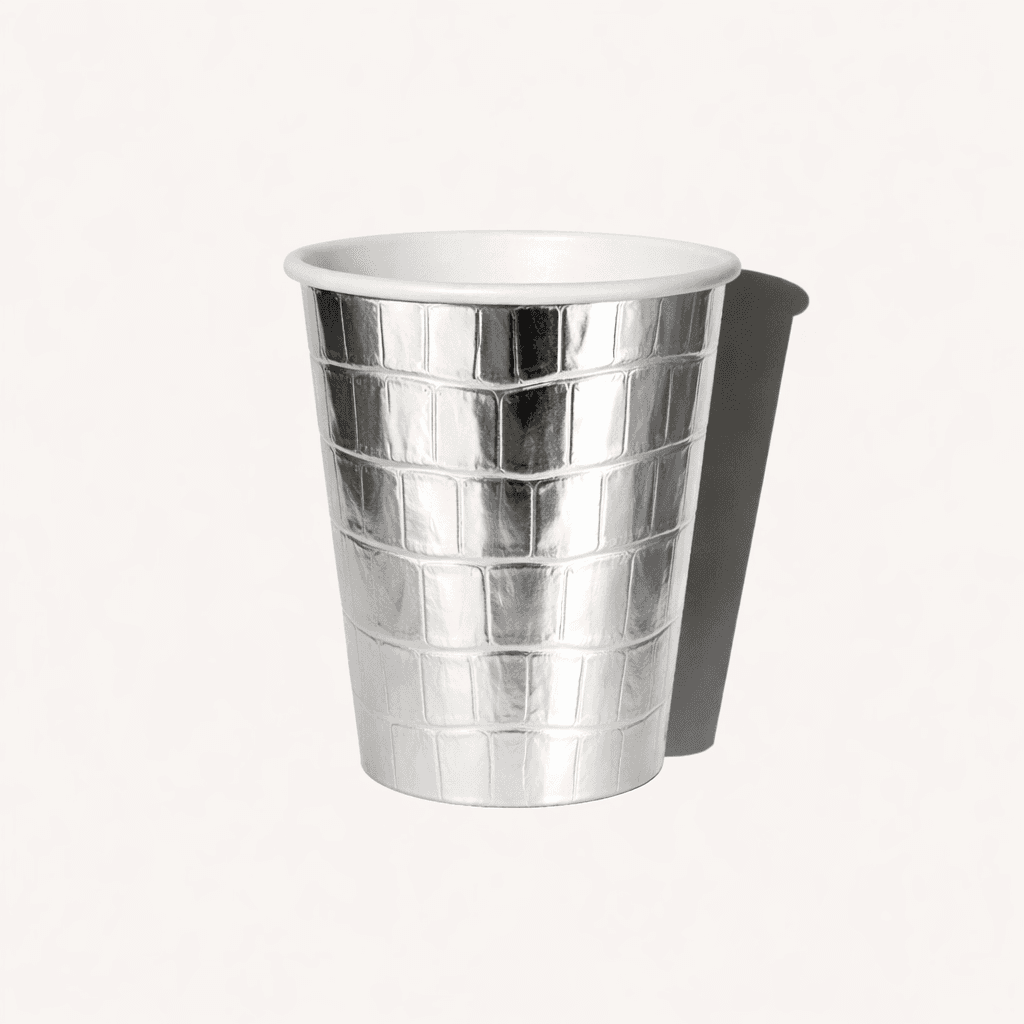

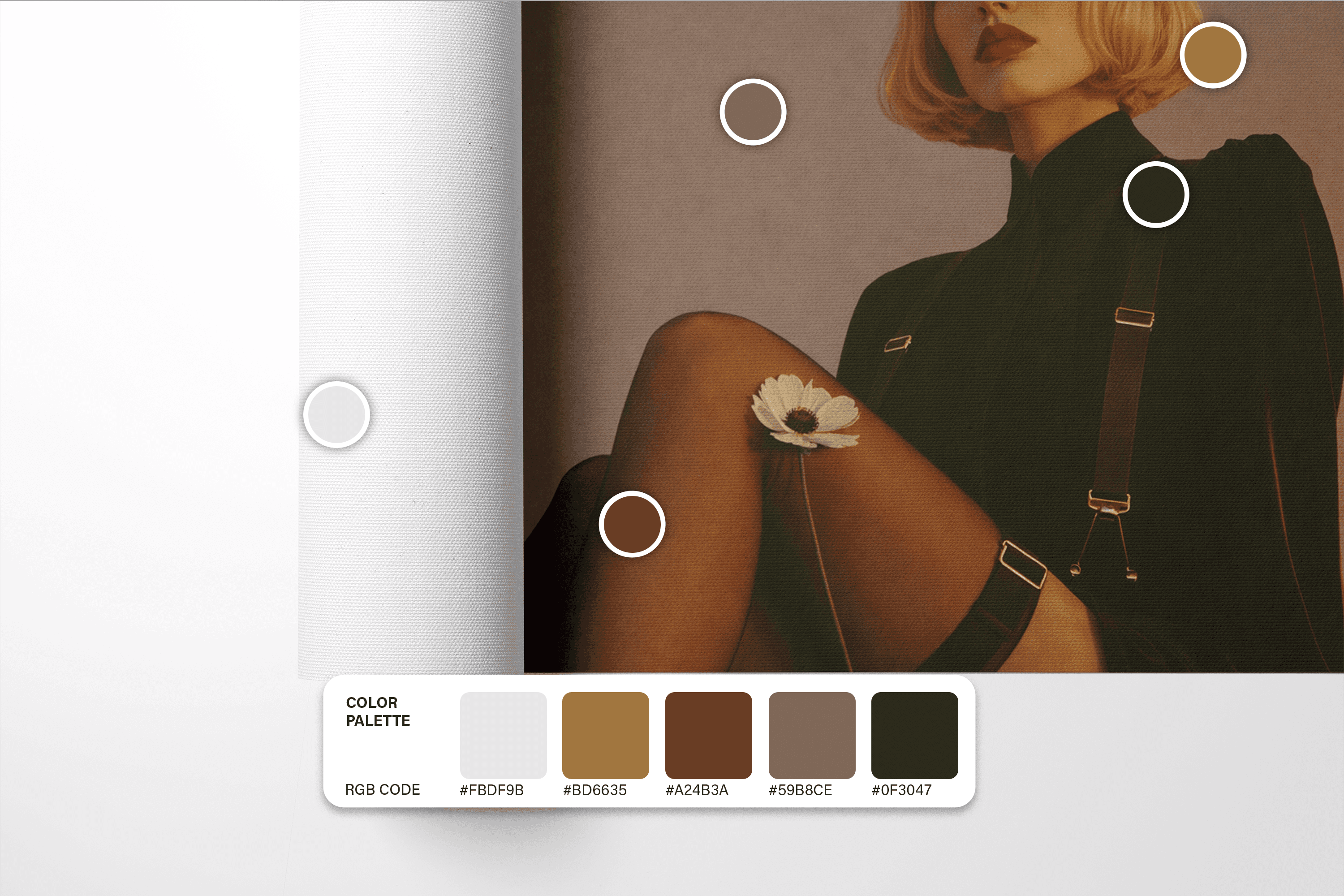

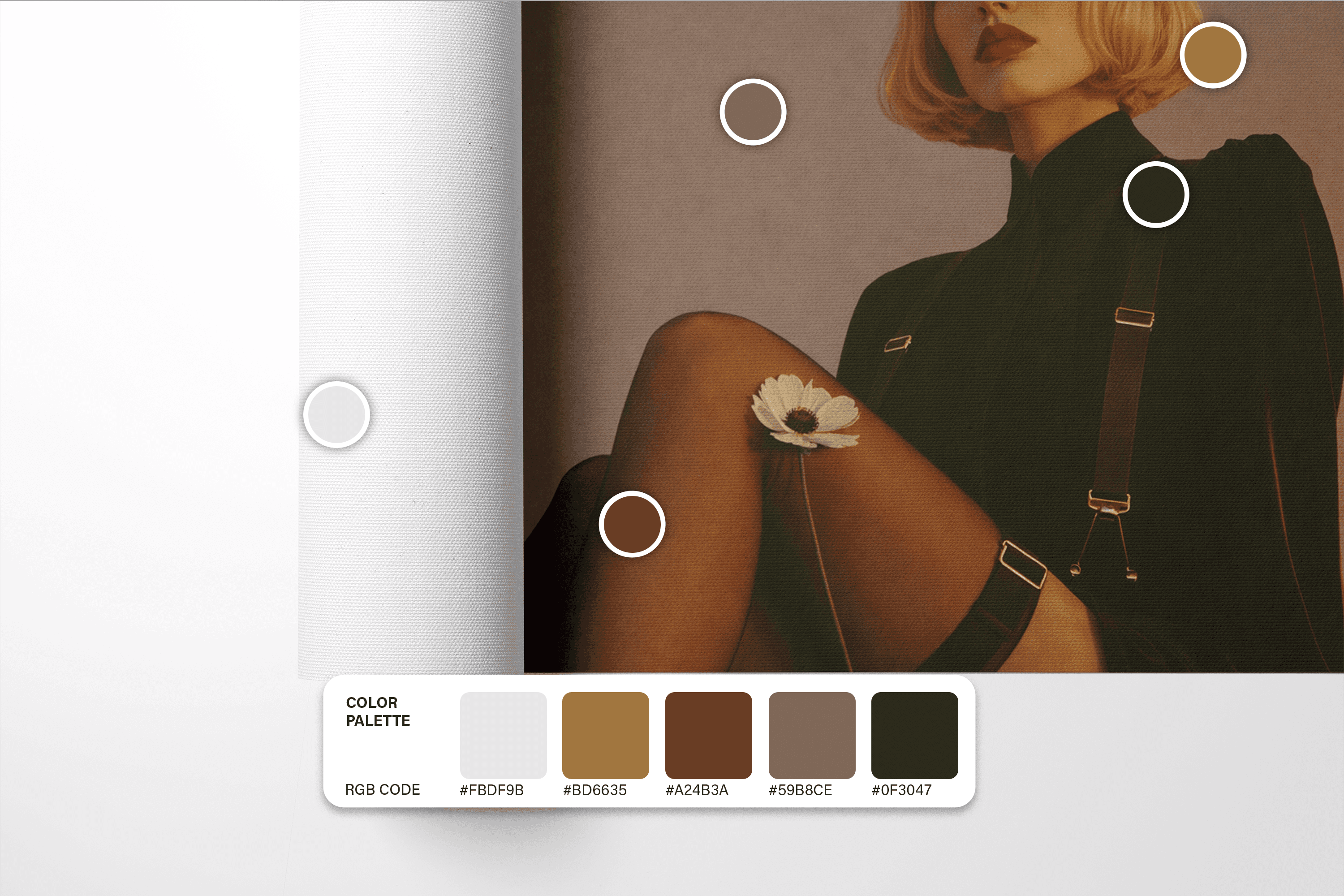

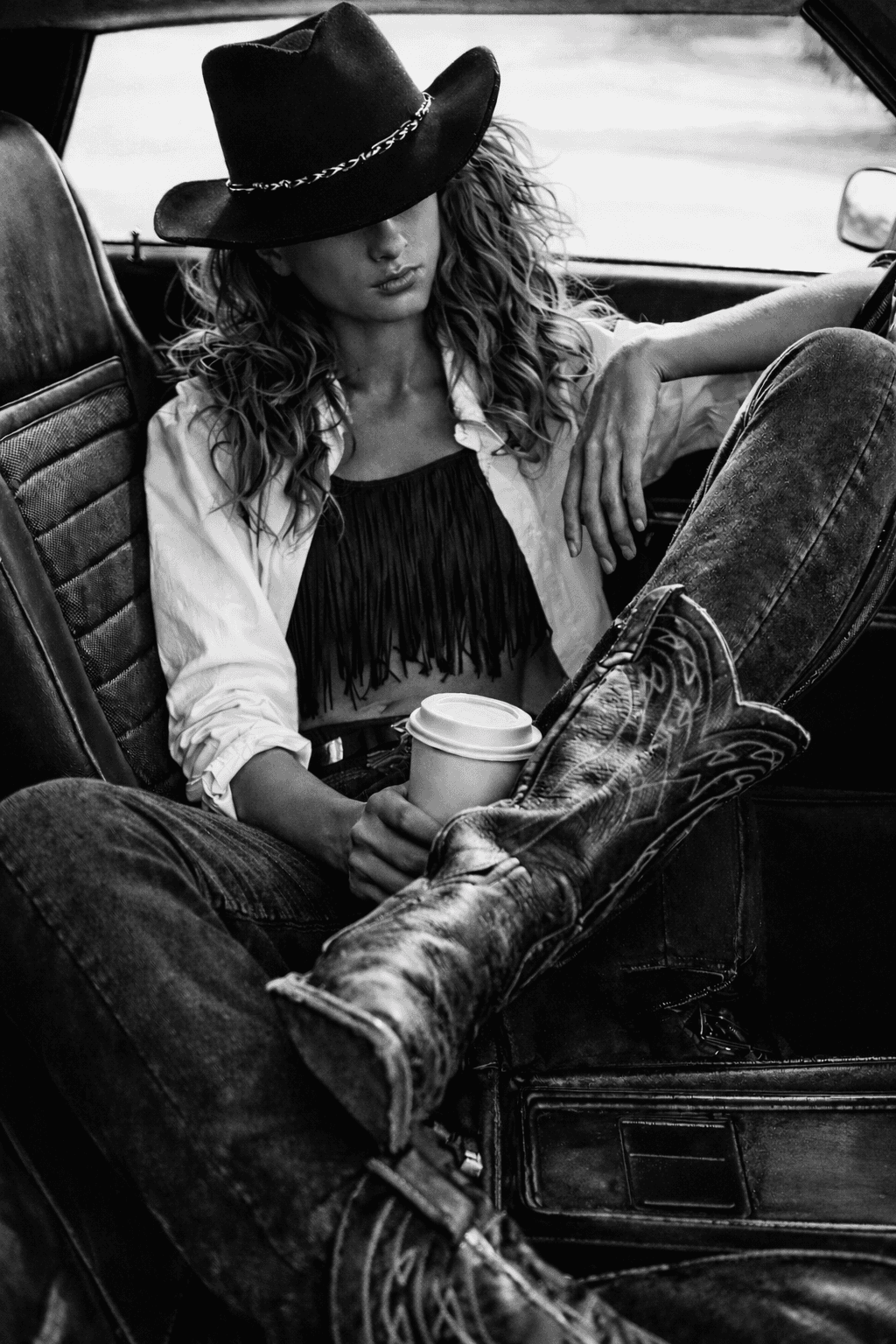

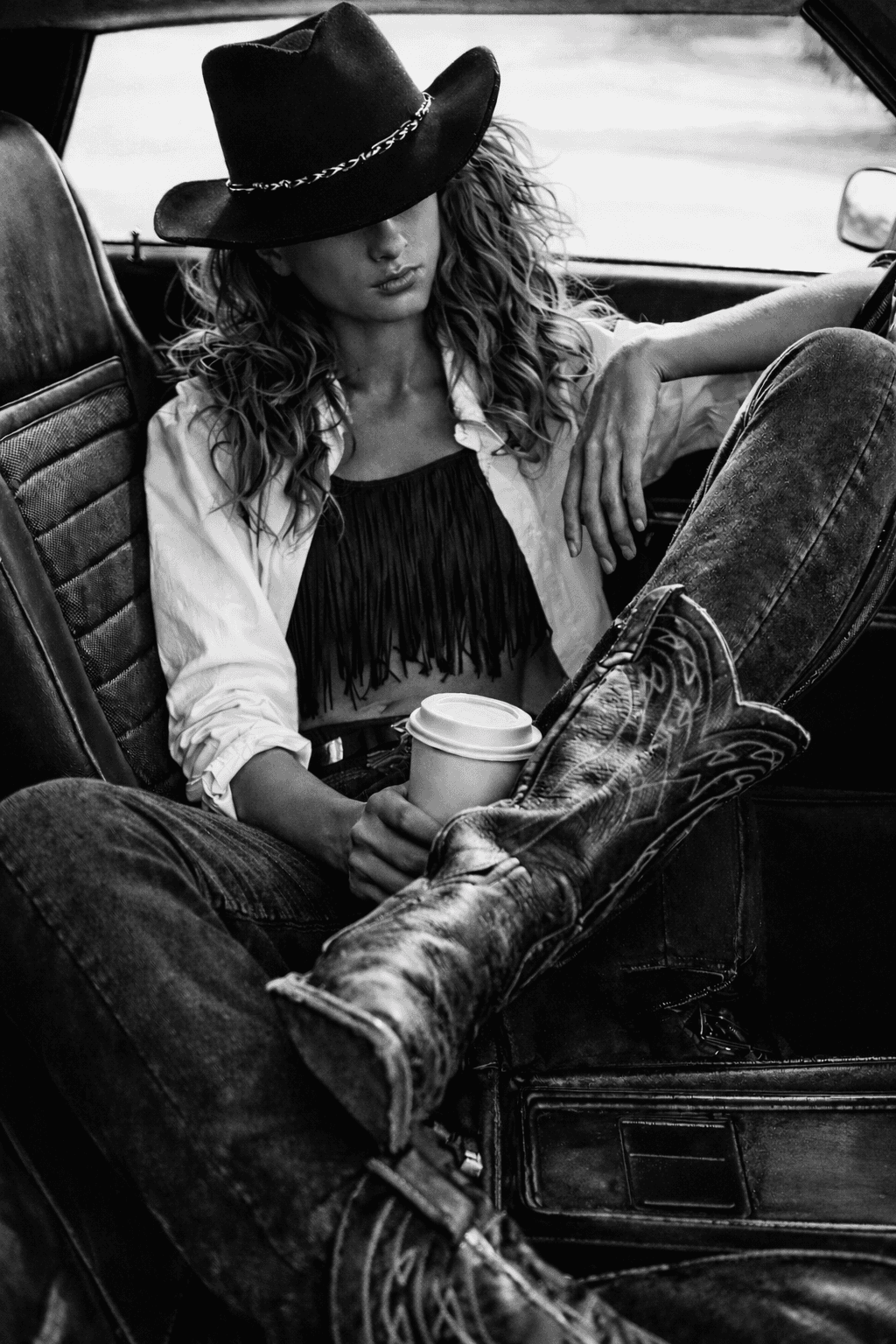

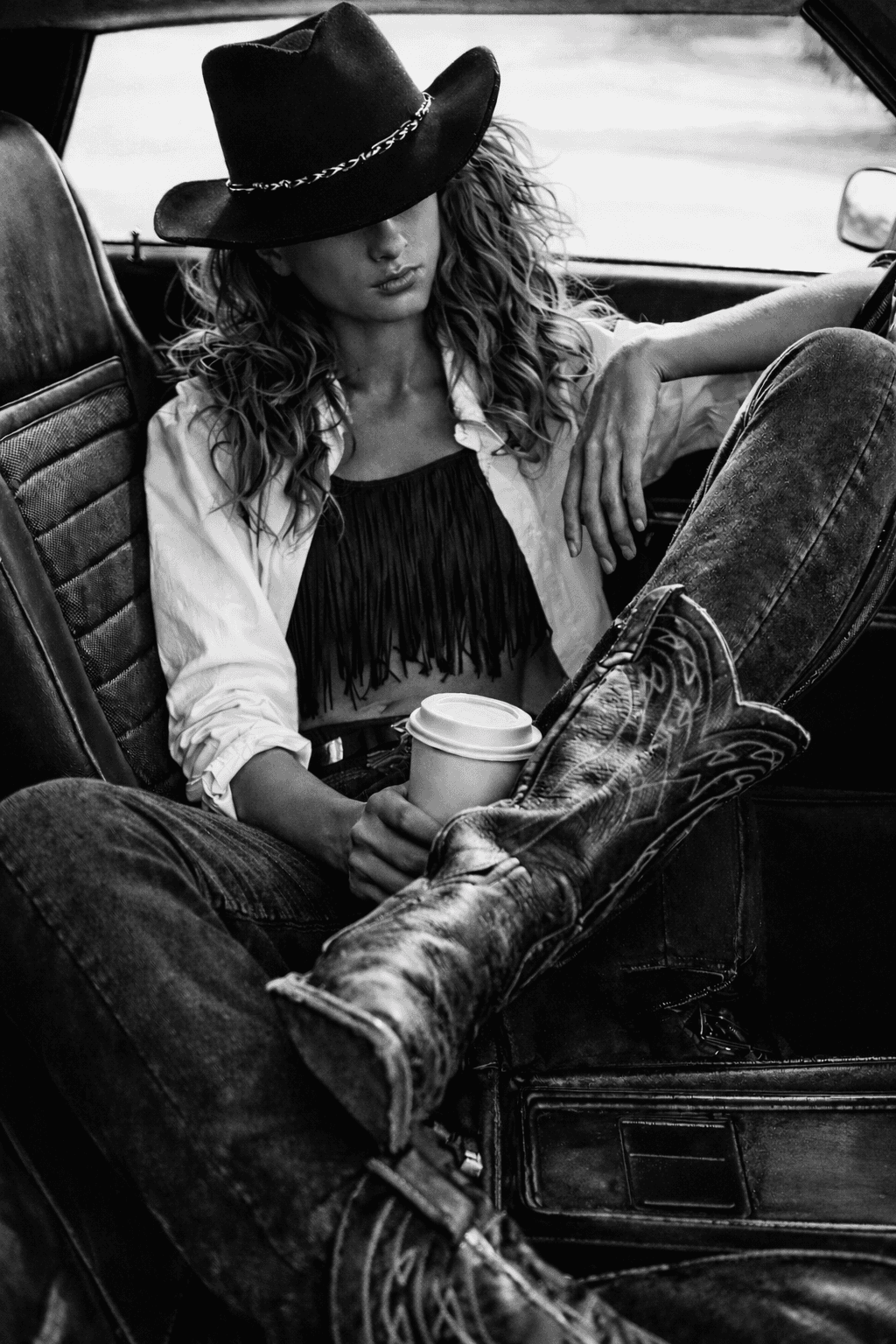

STUDIO-LED

Performance meets perception.

Integration of PHA into premium brand environments. Developed to meet exacting standards across colour, finish and perception

STUDIO-LED

Performance meets perception.

Integration of PHA into premium brand environments. Developed to meet exacting standards across colour, finish and perception

STUDIO-LED

Performance meets perception.

Integration of PHA into premium brand environments. Developed to meet exacting standards across colour, finish and perception

BUILT FOR REAL LIFE

Assured supply.

Engineered for performance and scale across hospitality, beauty, fashion, aviation and global events. Ready for real world demands.

BUILT FOR REAL LIFE

Assured supply.

Engineered for performance and scale across hospitality, beauty, fashion, aviation and global events. Ready for real world demands.

BUILT FOR REAL LIFE

Assured supply.

Engineered for performance and scale across hospitality, beauty, fashion, aviation and global events. Ready for real world demands.

Industry Awards

2025 Highlights

Recognised for design innovation.

Vogue Future Innovator. InnovationAus Award - Energy and Renewables. Global Recognition Award UK. Meaningful Business 100 Finalist.

Industry Awards

2025 Highlights

Recognised for design innovation.

Vogue Future Innovator. InnovationAus Award - Energy and Renewables. Global Recognition Award UK. Meaningful Business 100 Finalist.

Industry Awards

2025 Highlights

Recognised for design innovation.

Vogue Future Innovator. InnovationAus Energy and Renewables. Global Recognition UK. Meaningful Business 100 Finalist.

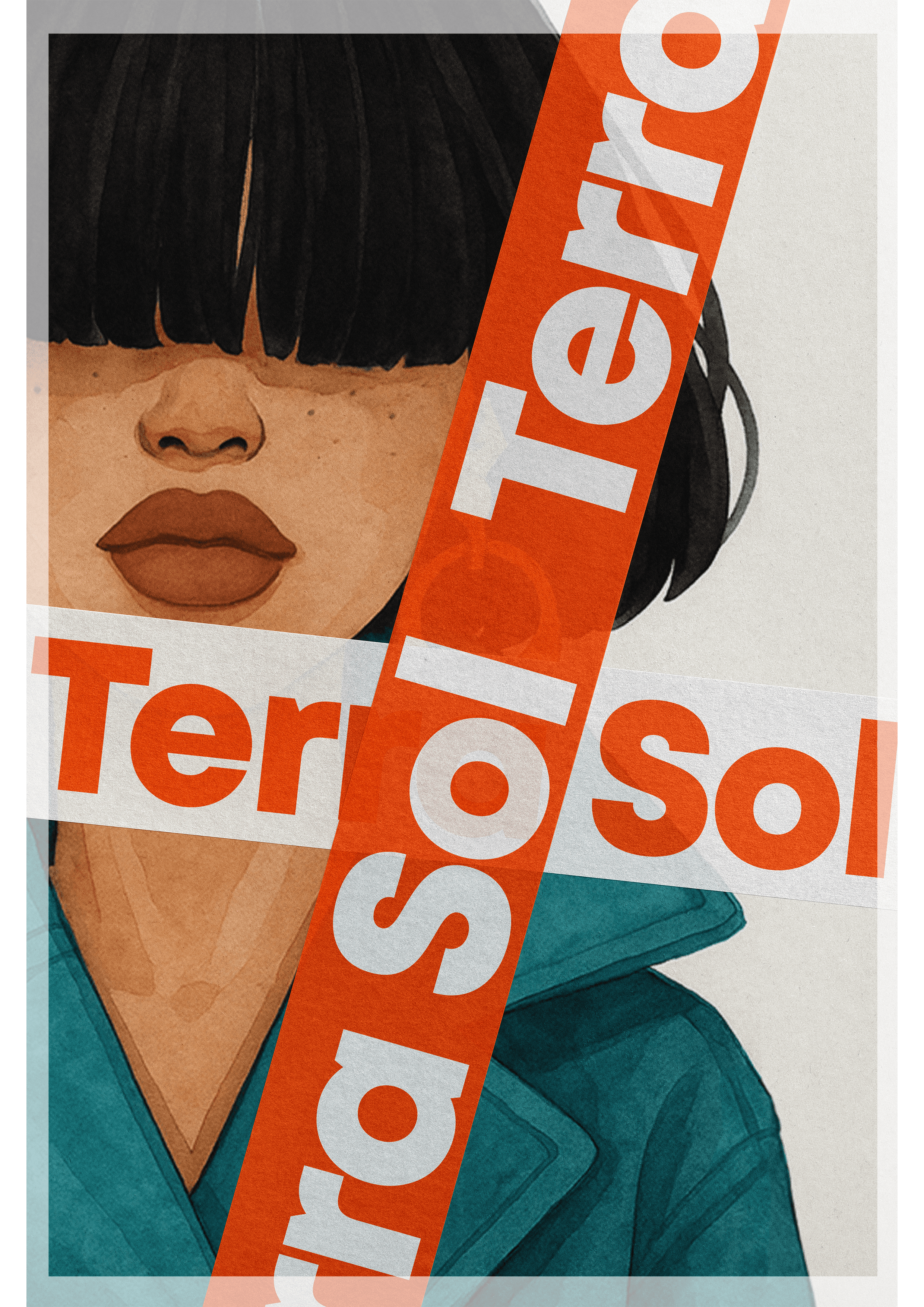

FEATURED

FEATURED

Vogue Magazine Future Innovator

Vogue Magazine Future Innovator

Terra Sol Founder and CEO Louise Sykes, featured in Vogue Magazine Australia’s December issue.

Terra Sol Founder and CEO Louise Sykes, featured in Vogue Magazine Australia’s December issue.

takeaway cups used daily (AUS)

takeaway cups used daily (AUS)

7.4M

takeaway cups used annually (AUS)

takeaway cups used annually (AUS)

2.7B

how long does it really take to break down?

how long does it really take to break down?

PET (yrs)

PET (yrs)

PET (yrs)

plastic (yrs)

plastic (yrs)

plastic (yrs)

PLA (yrs)

PLA (yrs)

PLA (yrs)

aqueous (yrs)

aqueous (yrs)

aqueous (yrs)

PHA (months)

PHA (months)

PHA (months)

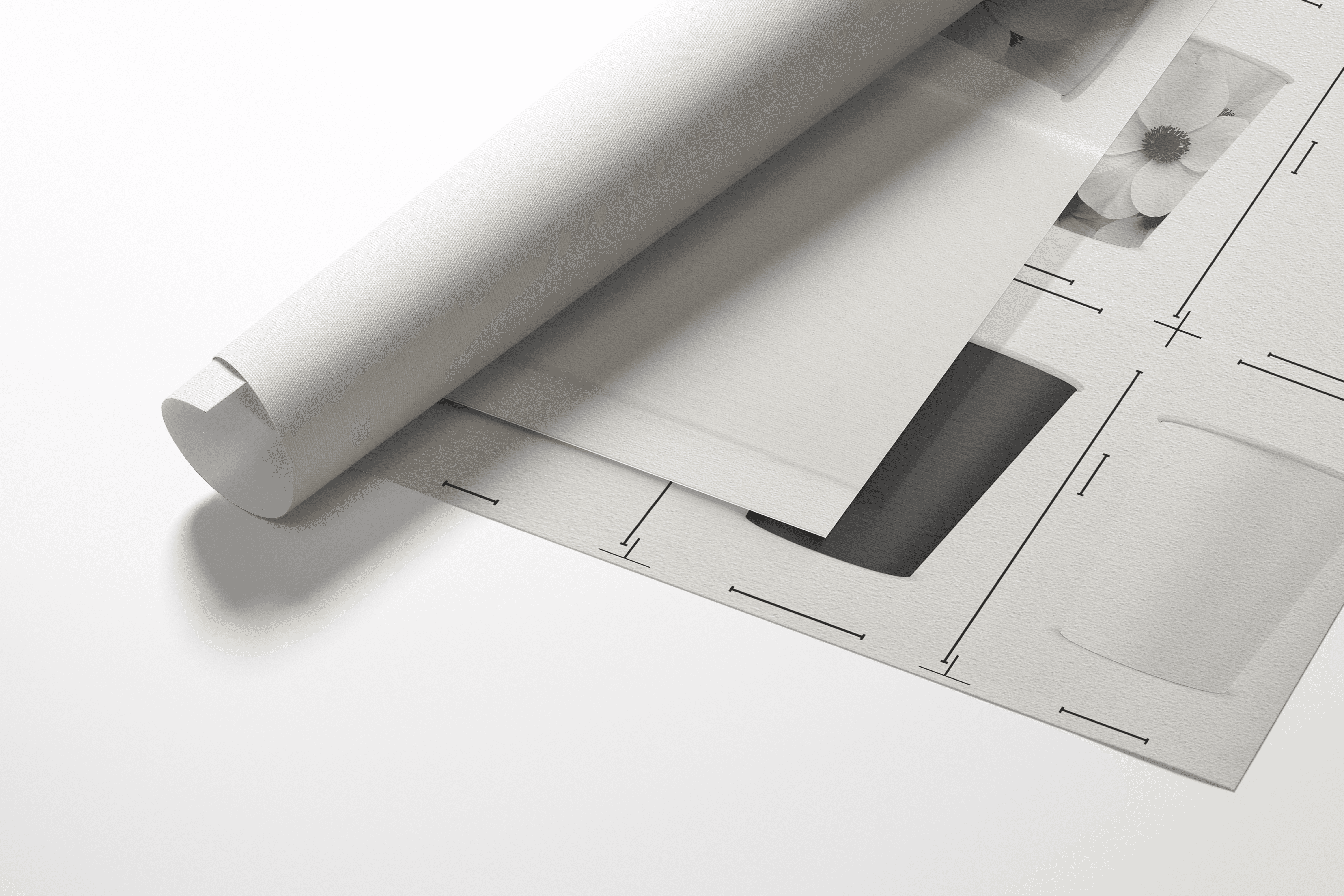

Terra Sol integrates advanced PHA into global brands, cafés and design houses, translating creative vision into scalable production.

Terra Sol integrates advanced PHA into global brands, cafés and design houses, translating creative vision into scalable production.

{01}

Creative Direction —

We shape products from the outset, aligning brand expression with material innovation to create a cohesive, commercially viable outcome.

Brand Positioning

Custom Design

Brand Guidelines

{01}

Creative Direction —

We shape products from the outset, aligning brand expression with material innovation to create a cohesive, commercially viable outcome.

Brand Positioning

Custom Design

Brand Guidelines

{01}

Creative Direction —

We shape products from the outset, aligning brand expression with material innovation to create a cohesive, commercially viable outcome.

Brand Positioning

Custom Design

Brand Guidelines

{02}

Communication —

We translate material integrity and environmental performance into clear, confident brand narratives.

Sustainable Messaging

Impact Communication

Transparency Guides

{02}

Communication —

We translate material integrity and environmental performance into clear, confident brand narratives.

Sustainable Messaging

Impact Communication

Transparency Guides

{02}

Communication —

We translate material integrity and environmental performance into clear, confident brand narratives.

Sustainable Messaging

Impact Communication

Transparency Guides

{03}

Development —

We develop scalable, high-performance PHA solutions engineered for real-world use.

Material Application

Performance Testing

Market-Ready Product

{03}

Development —

We develop scalable, high-performance PHA solutions engineered for real-world use.

Material Application

Performance Testing

Market-Ready Product

{03}

Development —

We develop scalable, high-performance PHA solutions engineered for real-world use.

Material Application

Performance Testing

Market-Ready Product

Begin the conversation.

Begin the conversation.

Begin the conversation.

Why Brands Choose Terra Sol

rationale

Built for Long-Term Partnership

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA. We help premium brands transition away from plastic by integrating advanced materials into real-world products while protecting performance, compliance and brand experience.

Why Brands Choose Terra Sol

rationale

Built for Long-Term Partnership

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA. We help premium brands transition away from plastic by integrating advanced materials into real-world products while protecting performance, compliance and brand experience.

Why Terra Sol?

rationale

Built for Long-Term Partnership

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA. We help premium brands transition away from plastic by integrating advanced materials into real-world products while protecting performance, compliance and brand experience.

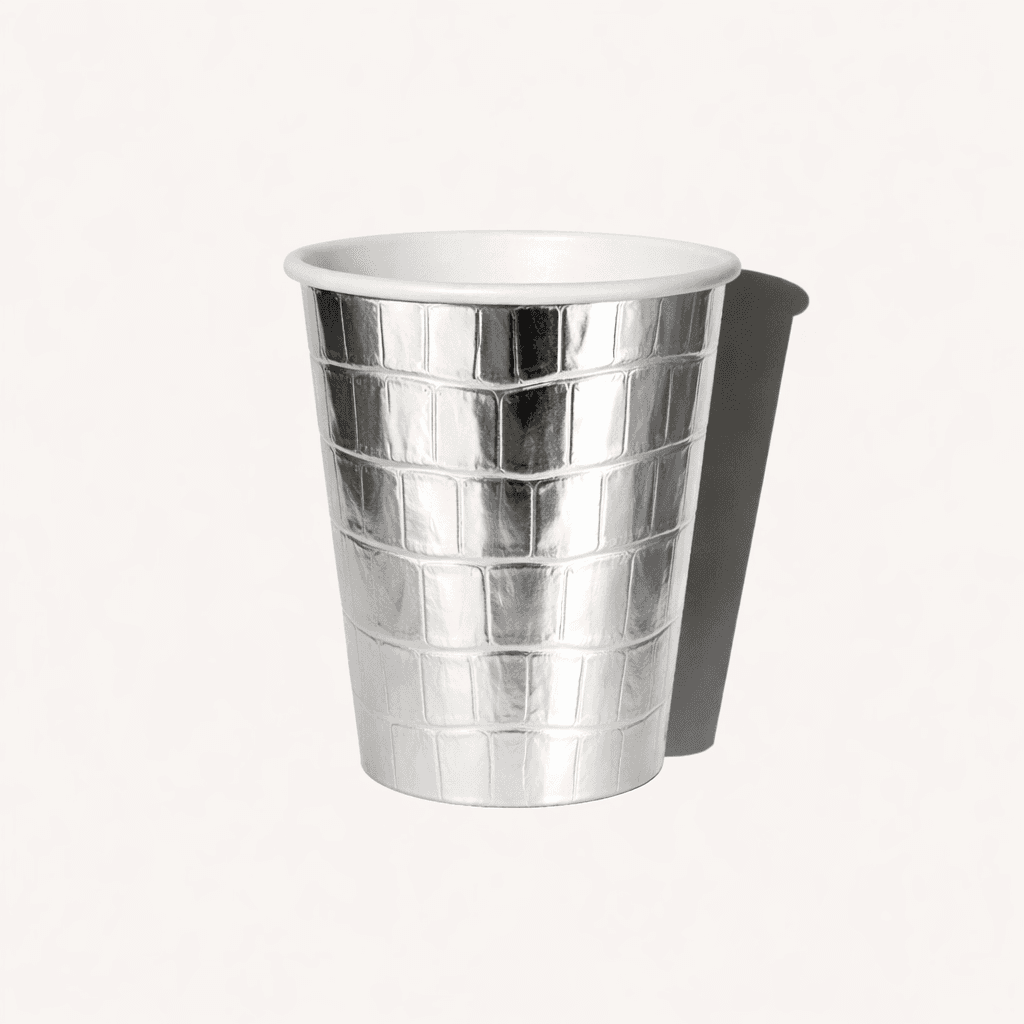

Design-Led from Day One

Every Terra Sol product begins with aesthetic intent. Colour, form and finish are considered first, shaping objects people want to use.

Integrated Performance

Integrated Performance

+

Function, durability and biodegradation are engineered into the design from the outset.

Function, durability and biodegradation are engineered into the design from the outset.

Elevated Positioning

Elevated Positioning

Sustainability that elevates brand perception while remaining commercially viable.

Sustainability that elevates brand perception while remaining commercially viable.

Australian Made

Australian Made

Designed in Sydney. Manufactured in Melbourne and Perth.

Designed in Sydney. Manufactured in Melbourne and Perth.

A Category First. The only PHA cup and lid set exclusive to Terra Sol.

A Category First. The only PHA cup and lid set exclusive to Terra Sol.

Recognised by Industry

Vogue, InnovationAus, MB100 and Global Recognition UK.

Vogue, InnovationAus, MB100 and Global Recognition UK.

Here for the Long Term

We build lasting partnerships, supporting brands from pilot to full rollout and beyond.

We build lasting partnerships, supporting brands from pilot to full rollout and beyond.

Designed for Real-World Conditions

Designed for Real-World Conditions

Our products biodegrade safely, even when waste systems fail, without leaving microplastics behind.

Our products biodegrade safely, even when waste systems fail, without leaving microplastics behind.

Verified

Verified

Materials and claims grounded in science, not spin.

Materials and claims grounded in science, not marketing.

Flexible & Scalable

Flexible & Scalable

From pilot to scale, supported by secure Australian manufacturing and reliable supply.

From pilot to scale, supported by secure Australian manufacturing and reliable supply.

From pilot to scale, supported by secure Australian manufacturing and reliable supply.

Hands-On Partnership

Hands-On Partnership

100% Founder-Led

100% Founder-Led

We stay closely involved, offering direct access and hands-on support whenever it’s needed.

We stay closely involved, offering direct access and hands-on support whenever it’s needed.

Design. Material. Impact.

Design. Material. Impact.

Design. Material. Impact.

Popular Queries

faq

Quick and clear answers to your key questions

Get clarity on PHA, our products and how we work with brands.

Popular Queries

faq

Quick and clear answers to your key questions

Get clarity on PHA, our products and how we work with brands.

Popular Queries

faq

Quick and clear answers to your key questions

Get clarity on PHA, our products and how we work with brands.

What is marine-safe PHA?

PHA is a bio-based polymer produced through natural fermentation. Engineered to perform like conventional plastic in everyday use, it biodegrades naturally in marine and soil environments without leaving microplastics behind. It represents a next-generation material designed to reduce long-term environmental impact while maintaining real-world durability.

How is PHA different from other sustainable materials?

Unlike recyclable plastics or many so-called compostables, PHA fully biodegrades without leaving persistent microplastics. While most compostable plastics require tightly controlled industrial facilities, PHA can break down in natural environments, including soil and marine conditions. It does not fragment. It returns safely to nature.

What does the transition to PHA look like?

We guide partners from concept through testing, specification and rollout. Our team remains closely involved to ensure alignment across creative, operational and sustainability priorities, reducing friction and accelerating adoption.

Does PHA perform like conventional plastic?

Yes. PHA is engineered to meet the functional and durability standards required for commercial applications. It offers strength, heat resistance and usability comparable to conventional plastics, enabling transition without compromising performance.

What happens if PHA ends up in landfill or the ocean?

PHA is designed to biodegrade safely even when waste systems fail. In natural environments, including marine conditions, it breaks down without leaving persistent microplastics. It does not rely solely on industrial composting to begin its biodegradation process.

Is PHA recyclable or compostable?

PHA can be composted within appropriate systems and is compatible with certain organic waste streams. However, its key advantage is that it does not rely exclusively on industrial composting to break down safely, unlike many compostable plastics.

Is PHA commercially competitive?

Yes. Terra Sol’s PHA products are commercially competitive with conventional materials. In most cases, transitioning to PHA is a material shift, not a budget increase. Backed by Australian manufacturing and scalable production, we support adoption without disrupting operational efficiency.

How does Terra Sol work with EcoPHA?

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA technology. We bridge material science and brand execution, integrating advanced PHA into scalable, real-world products across multiple sectors.

What is marine-safe PHA?

PHA is a bio-based polymer produced through natural fermentation. Engineered to perform like conventional plastic in everyday use, it biodegrades naturally in marine and soil environments without leaving microplastics behind. It represents a next-generation material designed to reduce long-term environmental impact while maintaining real-world durability.

How is PHA different from other sustainable materials?

Unlike recyclable plastics or many so-called compostables, PHA fully biodegrades without leaving persistent microplastics. While most compostable plastics require tightly controlled industrial facilities, PHA can break down in natural environments, including soil and marine conditions. It does not fragment. It returns safely to nature.

What does the transition to PHA look like?

We guide partners from concept through testing, specification and rollout. Our team remains closely involved to ensure alignment across creative, operational and sustainability priorities, reducing friction and accelerating adoption.

Does PHA perform like conventional plastic?

Yes. PHA is engineered to meet the functional and durability standards required for commercial applications. It offers strength, heat resistance and usability comparable to conventional plastics, enabling transition without compromising performance.

What happens if PHA ends up in landfill or the ocean?

PHA is designed to biodegrade safely even when waste systems fail. In natural environments, including marine conditions, it breaks down without leaving persistent microplastics. It does not rely solely on industrial composting to begin its biodegradation process.

Is PHA recyclable or compostable?

PHA can be composted within appropriate systems and is compatible with certain organic waste streams. However, its key advantage is that it does not rely exclusively on industrial composting to break down safely, unlike many compostable plastics.

Is PHA commercially competitive?

Yes. Terra Sol’s PHA products are commercially competitive with conventional materials. In most cases, transitioning to PHA is a material shift, not a budget increase. Backed by Australian manufacturing and scalable production, we support adoption without disrupting operational efficiency.

How does Terra Sol work with EcoPHA?

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA technology. We bridge material science and brand execution, integrating advanced PHA into scalable, real-world products across multiple sectors.

What is marine-safe PHA?

PHA is a bio-based polymer produced through natural fermentation. Engineered to perform like conventional plastic in everyday use, it biodegrades naturally in marine and soil environments without leaving microplastics behind. It represents a next-generation material designed to reduce long-term environmental impact while maintaining real-world durability.

How is PHA different from other sustainable materials?

Unlike recyclable plastics or many so-called compostables, PHA fully biodegrades without leaving persistent microplastics. While most compostable plastics require tightly controlled industrial facilities, PHA can break down in natural environments, including soil and marine conditions. It does not fragment. It returns safely to nature.

What does the transition to PHA look like?

We guide partners from concept through testing, specification and rollout. Our team remains closely involved to ensure alignment across creative, operational and sustainability priorities, reducing friction and accelerating adoption.

Does PHA perform like conventional plastic?

Yes. PHA is engineered to meet the functional and durability standards required for commercial applications. It offers strength, heat resistance and usability comparable to conventional plastics, enabling transition without compromising performance.

What happens if PHA ends up in landfill or the ocean?

PHA is designed to biodegrade safely even when waste systems fail. In natural environments, including marine conditions, it breaks down without leaving persistent microplastics. It does not rely solely on industrial composting to begin its biodegradation process.

Is PHA recyclable or compostable?

PHA can be composted within appropriate systems and is compatible with certain organic waste streams. However, its key advantage is that it does not rely exclusively on industrial composting to break down safely, unlike many compostable plastics.

Is PHA commercially competitive?

Yes. Terra Sol’s PHA products are commercially competitive with conventional materials. In most cases, transitioning to PHA is a material shift, not a budget increase. Backed by Australian manufacturing and scalable production, we support adoption without disrupting operational efficiency.

How does Terra Sol work with EcoPHA?

Terra Sol is the exclusive design and commercial partner for EcoPHA’s patented marine-safe PHA technology. We bridge material science and brand execution, integrating advanced PHA into scalable, real-world products across multiple sectors.

Still looking for answers or need a good chat?

Our team will guide you through our design process, project specifications and cost estimate.

Anything left out?

Anything left out?

Anything left out?

We shape design.

Design shapes impact.

Start the conversation. Choose the way that works for you.

In partnership with EcoPHA Biotech, Australia.

We shape design.

Design shapes impact.

Start the conversation. Choose the way that works for you.

In partnership with EcoPHA Biotech, Australia.

We shape design.

Design shapes impact.

Start the conversation. Choose the way that works for you.

In partnership with EcoPHA Biotech, Australia.